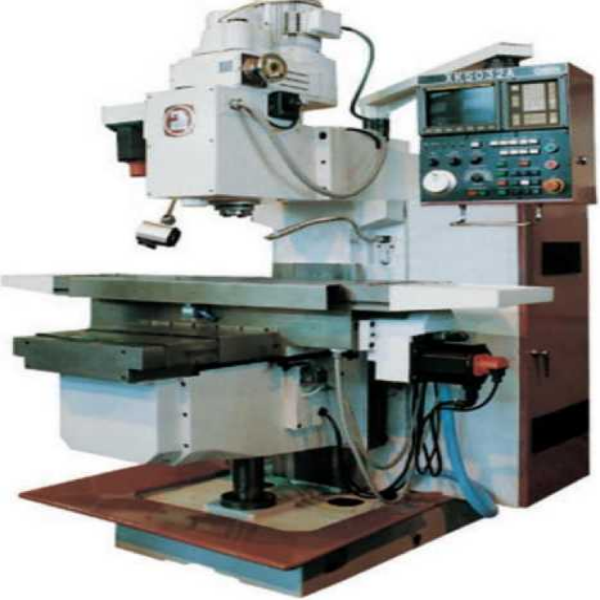

CNC Vertical And Horizontal Knee Type Milling Machine

Brand QIER WAJI CNC MACHINE

Product origin CHINA LIAONING

Delivery time 3 months

Supply capacity 2-5 units per month

1. CNC vertical lifting table milling machine has good rigidity and can withstand heavy duty cutting work.

2. CNC vertical lifting table milling machine has enough power and wide spindle speed range. Capable of high-speed cutting with cemented carbide cutting tools.

3. CNC vertical lifting table milling machine has a complete lubrication system, and important transmission parts and bearings have complete lubrication devices. At the same time, there is an indicator for frequent inspection.

Energy efficiency and cost advantages of CNC vertical lifting table milling machine:

Our CNC vertical lifting table milling machine has passed CE, UL and other authoritative energy efficiency certifications in Europe and the United States, and has been measured to save more than 20% energy compared to similar CNC vertical lifting table milling machine. The intelligent power adjustment system equipped with the CNC vertical lifting table milling machine can automatically optimize energy consumption according to the real-time processing load, and long-term operation can reduce electricity costs. The CNC vertical lifting table milling machine is equipped with an efficient cutting fluid circulation system that can reduce consumables expenses. Want to know how to optimize business operating costs through CNC vertical lifting table milling machine? Contact us for a customized solution for CNC vertical lifting table milling machine!

Introduction of CNC horizontal lifting table milling machine:

1. The main function of the bottom of CNC horizontal lifting table milling machine:

CNC horizontal lifting table milling machine is designed and developed independently by our company drawing on foreign advanced technology. The CNC system of CNC horizontal lifting table milling machine is selected from domestic and foreign famous manufacturers, which can realize three-axis control and three-axis linkage. The baht bed of CNC horizontal lifting table milling machine can complete the machining of straight lines, oblique lines, curved contours, etc., such as machining cams, template molds, butterfly grooves and other workpieces, and CNC horizontal lifting table milling machine is suitable for the machinery manufacturing industry.

2. The overall structure of CNC horizontal lifting table milling machine:

CNC horizontal lifting table milling machine consists of iron head, bed, base, lifting table, saddle, worktable, etc. The three CNC axes of X, Y, Z are table movement, sliding lame movement and lifting table movement respectively. Spindle sleeve movement of CNC horizontal lifting table milling machine is manual.

3. Main components of CNC horizontal lifting table milling machine:

The milling head, bed, base, lifting table, saddle, worktable, gearbox and other large parts of CNC horizontal lifting table milling machine are all made of high-strength, low-stress wear-resistant cast iron materials and treated with secondary aging. The main transmission parts of CNC horizontal lifting table milling machine (such as the main shaft and gears, etc.) are made of alloy steel to ensure the accuracy and service life of CNC horizontal lifting table milling machine. The main transmission system of CNC horizontal lifting table milling machine is driven by an ordinary AC motor, and the main transmission box is driven by an elastic coupling. There are three sets of sliding gears in the main transmission box. The manual transmission mechanism drives each slip gear, and the maggots become 18 kinds of rotation speed, and its rotation speed range is 30-1500r/min. The electromagnetic brake is used in the main transmission box to achieve rapid and stable braking of the main shaft.

4. CNC control system and attachments of CNC horizontal lifting table milling machine:

FANU-Oi CNC system (or SIEMENS 802D and domestic NC system), with 8.5' colour screen, RS-232 standard interface and manual impulse generator. The electric cabinet is mounted on the side face of column and IP54 guard standard is adopted to get full sealing structure. It is also equipped with a hot and cold exchanger. All the CNC cables are from FANUC Company. Please refer to the catalogue lor the main function of CNC system FANUC-Oi.

Test standards of column and knee type milling machine:

Each column and knee type milling machine will undergo 72 hours of continuous trouble-free operation test, high and low temperature environmental adaptability test and vibration simulation test before leaving the factory, so that the column and knee type milling machine can operate stably in different climates and working conditions in Europe and the United States. At the same time, the full-process quality inspection report of column and knee type milling machine is provided, so that the data of column and knee type milling machine can be visualized to prove to you that the quality of ourcolumn and knee type milling machine can withstand strict inspection. Do you have special requirements for the reliability of column and knee type milling machine? Contact us for test details of column and knee type milling machine.

Technical parameters of column and knee type milling machine:

Specification/Model | Unit | XK6032 | XK6132 | XK6040 | XK5032 | XK5032B | XK5042 | XK5040A |

Table Size (W x L) | mm | 320x1320 | 320x1320 | 400x1600 | 320x1320 | 320x1320 | 420x1300 | 400x1600 |

Max. Table Loading Capacity | kg | 300 | 300 | 500 | 300 | 300 | 300 | 500 |

Table Travel (X.Y.Z) | mm | 800/375/300 | 800/375/300 | 900/400/375 | 800/300/430 | 800/350/140 | 790/430/140 | 900/375/400 |

Distance Between Spindle Center and Table Surface | mm | 30-405 | 30-405 | 30-430 | Spindle Sleeve Stroke 100 | Spindle Sleeve Stroke 120 | ||

Max. Swivel Angle of Table | ±45° | Iron Head Rotation ±45° | Reading Head Rotation ±45° | |||||

Vertical Rapid Travel of Table (Adjustment) | mm | 400 | 450 | |||||

Distance Between Spindle Lace and Working Surface of Table | mm | 50-480 | 50-450 | 50-500 | 50-450 | |||

Distance from Back Side of Table to Bed Vertical Guideway | mm | 50-350 | 50-350 | 50-410 | 385 | |||

Distance from Main Spindle Center to Bed Vertical Guideway | mm | 385 | 450 | 450 | ||||

Taper in Spindle | ISO50 | ISO50 | ISO50 | ISO50 | IS040 | ISO40 | ISO50 | |

Range of Main Spindle Speed | r/min | 30-1500 | 30-1500 | 30-1500 | 30-1500 | (None and) 60-3000 | (None and) 60-3000 | 30-1500 |

Feeding Speed of X.Y Axes (Stepless) | mm/min | (X、Z) 10-3000 | (X、Z) 10-3000 | (X、Z) W-3000 | 10-3000 | 10-3000 | 10-3000 | 10-3000 |

Feeding Speed of Z Axis (Stepless) | mm/min | (Y) 10-1500 | (Y) 10-1500 | (Y) 10-1500 | 10-1500 | 10-3000 | 10-3000 | 10-1500 |

Quick Feeding Speed of X,Y Axes | mm/min | (X、Z) 3000 | (X、Z) 3000 | (X、Z) 3000 | 3000 | 3000 | 3000 | 3000 |

Quick Feeding Speed of Z Axis | mm/min | (Y) 15000 | (Y) 1500 | (Y) 1500 | 1500 | 3000 | 3000 | 1500 |

Quick Feeding Speed of Table Vertical Guideway | mm/min | 970 | 970 | |||||

Main Motor Power | kw | 7.5 | 7.5 | 11 | 7.5 | 4 | 4 | 11 |

Feeding Motor Torque | Nm | 12/22/12 | 12/22/12 | 22/30/22 | 12/12/22 | 6/6/6 | 6/6/6 | 12/12/30 |

Min. Resolution | mm | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.01 | 0.001 |

Positioning Accuracy | m | X0.02/Y.Z0.025 | X0.02/Y.Z0.025 | X0.042/Y.Z0.025 | X0.02/Y.Z0.025 | ±0.012 | ±0.012 | ±0.015 |

Re-Positioning Accuracy | mm | X0.018/Y.Z0.015 | X0.018/Y.Z0.015 | X0.020/Y.Z0.015 | X0.018/Y.Z0.015 | 0.01 | 0.01 | 0.01 |

天美直播Weight | kg | 3000 | 3000 | 4000 | 3200 | 2500 | 2800 | 5000 |

Overall Dimensions (L×W×H) | mm | 1958x2127x1790 | 1958x2127x1856 | 2320x2415x2080 | 1958x2080x2085 | 1850x1900x2450 | 1900x2100x2470 | 2558x2245x2440 |

Other models of column and knee type milling machine series:

Column and knee type milling machine XK6032,

Column and knee type milling machine XK6232,

Column and knee type milling machine XK6040,

Column and knee type milling machine XK5032,

Column and knee type milling machine XK5032B,

Column and knee type milling machine XK5042,

Column and knee type milling machine XK5040A.

Customization and after-sales of lifting milling machine:

We understand the strict requirements of lifting milling machine personalization and service timeliness in the European and American markets. We can customize the core parameters such as the spindle torque of the lifting milling machine and the workbench load-bearing of the lifting milling machine according to your special process needs for the lifting milling machine. We can also develop exclusive fixtures and processing solutions for the lifting milling machine, so that the lifting milling machine is perfectly adapted to precision machining scenarios such as aerospace and auto parts. For the after-sales aspects of lifting milling machine, we can guarantee that the reply will not exceed 6 hours at the latest. Whether you have customized needs for lifting milling machine, or want to know more about the after-sales details of lifting milling machine, please feel free to contact us!

Main functions of lifting milling machine:

Our company designs and manufactures CNC vertical and vertical milling machines based on traditional horizontal knee milling machines and overseas advanced technology. The CNC systems of these machines are provided by well-known suppliers in our company in China and overseas, capable of three-axis control and simulated skin three-axis control. The machine can perform milling operations along linear, inclined and contour lines, such as machining cam wheels, sample plates, molds, helical chutes. The machine is suitable for all parts of the manufacturing industry and military industry.

Application of lifting milling machine:

1. Mold manufacturing industry: lifting milling machine is mainly used for cavity, core, and parting surface processing of small and medium-sized molds. Lifting milling machine can realize the processing of complex curved surfaces and special-shaped structures, and lifting milling machine can meet the requirements of molds for dimensional accuracy and surface roughness.

2. Auto parts industry: lifting milling machine is suitable for the processing of small precision parts of automobiles. Lifting milling machine can complete the plane milling, step milling, and hole system machining of parts in batches, and lifting milling machine can ensure the consistency of batch parts through program reuse.

3. Aerospace field: lifting milling machine can be used to process small structural parts in the aerospace field. Lifting milling machine can handle aluminum alloy, titanium alloy and other commonly used aviation materials, while CNC horizontal boring mill can meet the strict standards of dimensional tolerances of parts in this field.

4. Medical device industry: CNC horizontal boring mill can process small precision parts of medical devices. CNC horizontal boring mill can realize fine milling of parts, and CNC horizontal boring mill can reduce the thermal deformation of processing by installing a cooling system to ensure the processing quality.

5. General machinery and hardware industry: CNC horizontal boring mill, as a general processing equipment, can complete the multi-process processing of small and medium-sized mechanical parts. CNC horizontal boring mill has strong flexibility and can quickly switch machining workpieces. CNC horizontal boring mill is suitable for multi-variety and small-batch production needs.

Why would you choose us:

1. Our company has rich experience and deep technical accumulation in the field of machine tool manufacturing, and can continue to launch high-quality CNC horizontal boring mill that meet market demand, with advanced technology and reliable quality.

2. From the procurement of raw materials for CNC horizontal boring mill to the assembly of CNC horizontal boring mill, we strictly follow the international quality management system standards to control the CNC horizontal boring mill in every aspect. The key parts of CNC horizontal boring mill are made of high-quality materials. After a number of precision machining and testing processes, the performance of CNC horizontal boring mill is stable and the accuracy is long-lasting. The quality of the CNC horizontal boring mill we produce far exceeds industry standards, allowing buyers to purchase with confidence.

3. Our CNC horizontal boring mill has been widely used in aerospace, automobile manufacturing, mold processing and other mainstream industrial fields in Europe and the United States. CNC horizontal boring mill has many successful cases and a good reputation in the European and American markets.

Company profile:

QIER MACHINE GROUP DALIAN WAJI CNC MACHINE Co., Ltd. is a joint-stock enterprise jointly invested by QIER 天美直播Group affiliated to China General Technology Group and the former DALIAN WAFANGDIAN MACHINE GROUP Co., LTD., (WAFANGDIAN HEAVY MACHINE) in 2003. The company is located in Dalian Changxing Island industrial park, the beautiful shore of Bohai Sea. Our company registered paid-in capital of 80 million, factory covers an area of 13 acres that is a modern garden factory.

The leading products include swiveling diameter ranging from 400mm to 5000mm single and double column vertical lathe both CNC and conventional type, our products have already sale over 30 different provinces and autonomous regions in civil market. Marketing share of the same kind has already been over 40% for abroad. So far, we have already exported our products to 38 different countries and regions, many products have already filled the blank in China and come up to the world advanced level.

The company has already had a sales network spread all over China. We will keep our promise, good quality of products and have courage to take responsibility. Sincerely hope we can supply the best products, the best service in the most competitive price. Hoping establish multi-mode cooperation with new and old friends all around the world. Let us be the real partner.