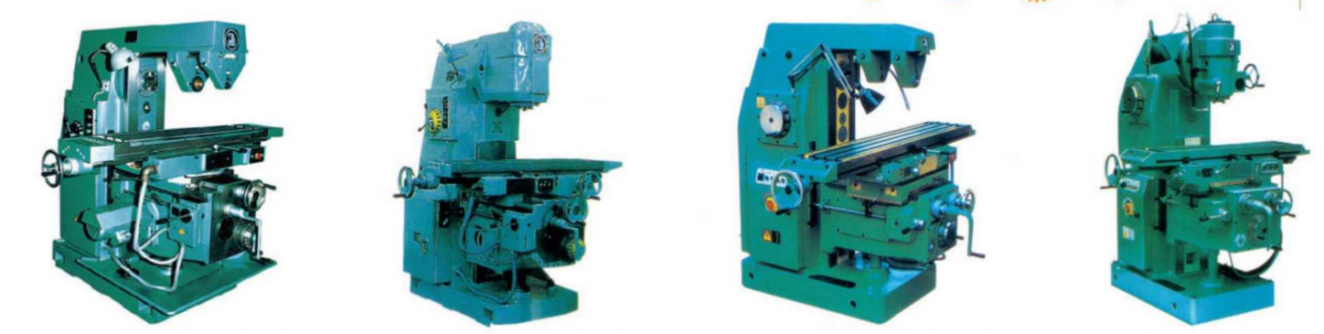

Conventional Knee Type Milling Machine

Brand QIER WAJI CNC MACHINE

Product origin CHINA LIAONING

Delivery time 3 months

Supply capacity 2-5 units per month

1. The body of the vertical knee mill is made of high-grade cast iron, which has high precision and long life after artificial aging treatment.

2. The main shaft of vertical knee mill is made of chrome molybdenum alloy, equipped with precision grade angular contact bearings, quenched and tempered and finely ground, with strong cutting force and high precision.

Welcome to the product display page of vertical knee mill! We have always used strict standards to build high-quality vertical knee mill. From the processing of parts of vertical knee mill to the assembly of the whole machine of vertical knee mill, every process follows the international leading technology and quality control system. If you wish to visit the production process of vertical knee mill on the spot and learn more about the manufacturing details of vertical knee mill, we always welcome you to visit the factory. We will be very honored to help you book air tickets and hotel accommodation to make your study trip more worry-free. If you want to make an appointment for a visit, or to learn more about the technical parameters of vertical knee mill, the customized solutions of vertical knee mill, and the details of cooperation, please feel free to contact us. We look forward to cooperating with you!

Introduction of vertical knee mill:

QIER MACHINE GROUP DALIAN WAJI CNC MACHINE Co., started producing the first milling machine in my country in 1952, and has now developed and produced the third-generation products, including X5030A, X5032A vertical lift table gun bed and X6130A, X6132B universal lift table milling machine, It has been among the best in previous quality evaluations in the same industry, and has continuously won the title of high-quality products from the Ministry of Machinery.

Environmental protection and sustainability of vertical knee mill:

Our vertical knee mill has always practiced the concept of green manufacturing from design to production. Vertical knee mill uses energy-saving motors and recyclable environmentally friendly materials. The production process of vertical knee mill strictly follows the ISO 14001 environmental management system standard. When vertical knee mill is running, through the optimized noise reduction structure design, the noise value generated by vertical knee mill is much lower than the industry standard. Vertical knee mill can also be equipped with an efficient cutting fluid filtration and recovery system to reduce waste liquid discharge and reduce cutting fluid usage. Vertical knee mill relies on the characteristics of low noise, low emissions, energy saving and high efficiency, and fully complies with the stringent environmental protection regulations and standards in Europe and the United States. Vertical knee mill can help companies realize the transformation of green production.

Specifications of vertical knee mill:

Specification/Model | Unit | X6130 | X6132C | X6140 | X5030A | X5032A | XW5032 | X5040j |

Working Area of Table (W×L) | mm | 300×1150/300×1500 | 320×1320 | 400×1700 | 300×1150/300×1500 | 320×1320 | 320×1320 | 400×1700 |

No. of T-slot of Table×顿cmension×顿istance | 3×14贬9×75尘尘 | 3×18贬9×80尘尘 | 3×18贬9×100尘尘 | 3×14贬9×75尘尘 | 3×18贬9×80尘尘 | 3×18贬9×80尘尘 | 3×18贬9×100尘尘 | |

Max. Swrvel Angle of Table | ±45° | ±45° | ±45° | |||||

Milling Head Swivel Deg | ±45° | ±45° | ±45° | |||||

Travel of Table Manual/Powerlongrtudinal | mm | 680/780 | 800/790 | 1000/990 | 680/780 | 800/790 | 800/790 | 1000/990 |

Travel of Table Manual/Powercross | rmn | 235 | 330/320 | 375/365 | 235 | 300/290 | 300/290 | 375/365 |

Travel of Table Manual/Power: Vertical | mm | 400 | 400/390 | 450/440 | 400 | 430/420 | 430/420 | 450/440 |

Table Feeds Speed: Longitudinal. Cross, Vertical | mm/min | 12-720, 4-240 | 12-1000, 4-333 | 12-1000, 4-333 | 12-720, 4-240 | 12-1000, 4-333 | 12-1000, 4-333 | 12-1000, 4-333 |

Table Feed Step | 14 | 18 | 18 | 14 | 18 | 18 | 18 | |

Spindle | 7:24 No.40 | 7:24 No.50 | 7:24 No.50 | 7:24 No.40 | 7:24 No.50 | 7:24 No.50 | 7:24 No.50 | |

Spindle Speed | r/min | Level 35-1600 | Level 30-1500 | Level 30-1500 | Level 36-1600 | Level 30-1500 | Level 30-1500 | Level 30-1500 |

Rapid Moving Speed of Table (Longitudinal、Transversal/Vertical) | mm | 2400/800 | 2400/800 | 2400/800 | 2400/800 | 2400/800 | 2400/800 | 2400/800 |

Distance Between Spindle Center and Table Surface | mm | 20-420 | 30-430 | 30-480 | ||||

Spindle Sleeve Moving | mm | 60 | 100 | 120 | ||||

Distance Between Spindle Face and Working Surface of Table mm | mm | 40-440 | 60-490 | 60-490 | 60-510 | |||

Motor Power of Main Drive KW | KW | 4 | 7.5 | 11 | 4 | 7.5 | 7.5 | 11 |

Motor Power of Feed KW | KW | 0.75 | 1.5 | 3 | 0.75 | 1.5 | 1.5 | 3 |

Motor Power of Cooling Pump KW | KW | 0.04 | 0.125 | 0.125 | 0.04 | 0.125 | 0.125 | 0.125 |

Overall Dimensions (L×W×H) mm | mm | 1690×1535×1630 | 2275×1810×1790 | 2715×2245×2080 | 1740×1485×1870 | 2225×1810×2050 | 2225×1810×2050 | 2715×2245×2495 |

Packing Case Overall Dimensions (L×W×H) mm | mm | — | 2300×2210×2200 | 2800×2380×2300 | 2370×2210×2390 | 2370×2210×2390 | 2800×2380×2450 | |

Net Weight kg | kg | 2100 | 3000 | 4300 | 2200 | 3100 | 3200 | 4900 |

Gross Weight | kg | 2900 | 3670 | 4900 | 3000 | 4700 | 4900 | 5600 |

Advantages of vertical knee mill:

The bed adopts square guide rail with good rigidity.

The thermal deformation of the main shaft is small, the transverse screw is arranged in the middle of the saddle, and the machining accuracy is high.

The main castings are made of alloy wear-resistant cast iron with long service life.

Technical advantages of knee mill vs vertical mill:

Our company's knee mill vs vertical mill is leading in manufacturing technology. Knee mill vs vertical mill adopts high-precision guide rail grinding technology. The ultra-precision machined guide rail can control the straightness error of the knee mill vs vertical mill to the micron level, which can improve the stability of the knee mill vs vertical mill when it is running, and allow the knee mill vs vertical mill to maintain high-precision machining standards under long-term and high-intensity operations.

Other models of the knee mill vs vertical mill series:

Knee mill vs vertical mill X6130,

Knee mill vs vertical mill X6132C,

Knee mill vs vertical mill X6140,

Knee mill vs vertical mill X5030A,

Knee mill vs vertical mill X5032A,

Knee mill vs vertical mill X5032,

Knee mill vs vertical mill X5040.

Application case of horizontal knee milling machine:

In the European and American markets, our horizontal knee milling machine has helped many companies achieve production upgrades. Taking an American auto parts manufacturer as an example, after introducing our horizontal knee milling machine, through the excellent cutting performance and stability of the horizontal knee milling machine, the processing efficiency of the automobile engine block has been increased by 30%, and the scrap rate has been reduced from 3% to 0.8%. This kind of real case about horizontal knee milling machine fully proves the powerful performance and reliability of horizontal knee milling machine in actual production.

Customized solution of horizontal knee milling machine:

We understand the differentiated needs of horizontal knee milling machine in different production scenarios, so we provide European and American buyers with a full range of customized services for horizontal knee milling machine. Whether it is the size of the workbench of the horizontal knee milling machine, the spindle speed range of the horizontal knee milling machine, or the capacity of the tool library, the horizontal knee milling machine can be flexibly adjusted according to your production scale and process requirements. For the special processing technology of horizontal knee milling machine, we can tailor the personalized configuration plan of horizontal knee milling machine for you, so that the performance of horizontal knee milling machine fits perfectly with your production needs, and create an exclusive and efficient processing horizontal knee milling machine.

Company profile:

QIER MACHINE GROUP DALIAN WAJI CNC MACHINE Co., Ltd. is a joint-stock enterprise jointly invested by QIER 天美直播Group affiliated to China General Technology Group and the former DALIAN WAFANGDIAN MACHINE GROUP Co., LTD., (WAFANGDIAN HEAVY MACHINE) in 2003. The company is located in Dalian Changxing Island industrial park, the beautiful shore of Bohai Sea. Our company registered paid-in capital of 80 million, factory covers an area of 13 acres that is a modern garden factory.

The leading products include swiveling diameter ranging from 400mm to 5000mm single and double column vertical lathe both CNC and conventional type, our products have already sale over 30 different provinces and autonomous regions in civil market. Marketing share of the same kind has already been over 40% for abroad. So far, we have already exported our products to 38 different countries and regions, many products have already filled the blank in China and come up to the world advanced level.

The company has already had a sales network spread all over China. We will keep our promise, good quality of products and have courage to take responsibility. Sincerely hope we can supply the best products, the best service in the most competitive price. Hoping establish multi-mode cooperation with new and old friends all around the world. Let us be the real partner.