CNC Heavy Duty Horizontal Lathe

Brand QIER WAJI CNC MACHINE

Product origin CHINA LIAONING

Delivery time 3 months

Supply capacity 2-5 units per month

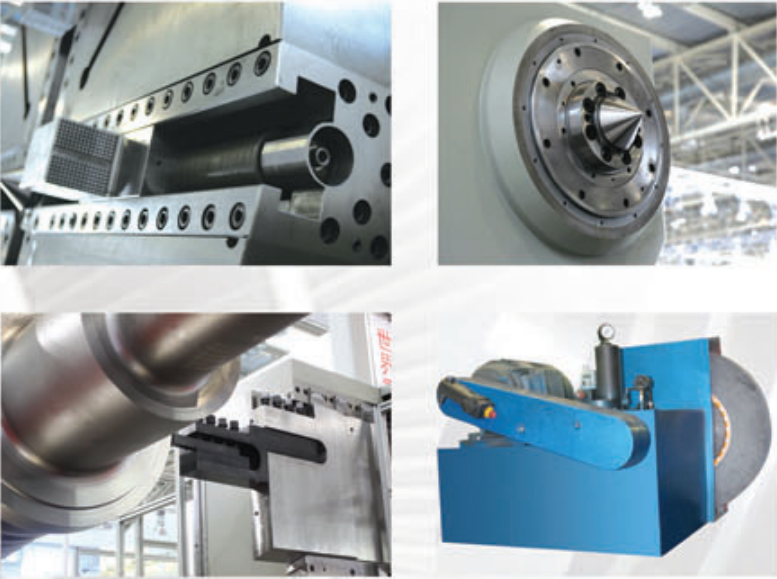

1. CNC horizontal lathe machine is suitable for high-speed steel, carbide steel and other tools, CNC horizontal lathe machine for ferrous, non-ferrous and some non-metallic shaft, cylinder and disc parts, turning the outer circle, end face, grooving , cutting, boring, etc.

2. The main drive of the CNC horizontal lathe machine is driven by a DC motor, and the speed range of the main shaft is realized through a mechanical three-speed speed change.

3. CNC horizontal lathe machine adopts double row short cylindrical roller bearing with high precision and adjustable radial clearance. The optimized design adopts larger spindle diameter and optimal supporting span, which improves the rotation accuracy of the spindle and the dynamic and static conditions.

Delivery and after-sales of CNC horizontal lathe machine:

We understand the strict requirements of buyers for the response speed of the CNC horizontal lathe machine supply chain, and have established a full-process and efficient delivery system of CNC horizontal lathe machine for this purpose. Relying on the geographical advantages of Dalian Lingang Industrial Zone and the global logistics network, we can realize that the delivery cycle of CNC horizontal lathe machine is 20% shorter than the industry average. In terms of after-sales guarantee, we have built a rapid response mechanism. When the CNC horizontal lathe machine is abnormal, as long as you contact us, we will reply to you within 6 hours and provide a solution for the CNC horizontal lathe machine.

Not sure which CNC horizontal lathe machine best meets your production needs? Leave your processing materials, workpiece size, expected output and other information, we will accurately match the most suitable CNC horizontal lathe machine model for you, and attach a detailed comparison and analysis of CNC horizontal lathe machine to help you easily choose CNC horizontal lathe machine.

Introduction of CNC horizontal lathe machine:

1. There are two structures of the bed assemblies available. One is the structure of the four guide separated bed assemblies and the other is of two guideways on one integrated bed assembly.

2. The main transmission of horizontal cnc lathe is driven by DC motor, through two-step mechanical transmission, to achieve the spindle speed range of 1:200. The center of horizontal cnc lathe adopts short taper flange structure. The tailstock and its sleeve of horizontal cnc lathe are driven by motor.

3. There are workpiece bed assembly and carriage bed assembly available in this structure. The closed-type constant flow hydrostatic uideways are provided for the transversal and longitudinal travels of the carriage. Ball screws are provided for the transversal travel transmission. For the longitudinal travel transmission, there are imported high precision double pinion-rack transmitting pair, which teeth surfaces have been hardened and ground, or optional hydrostatic worm rack transmitting pair. It is available for full closed loop control.

4. The slide guideways of horizontal CNC lathe are provided for the transversal and longitudi-nal travel of the carriage. Ball screws are provided for the transversal travel transmission. For the longitudinal travel transmission, rack transmitting pair, which teeth surfaces have been hardened and ground. It is in the box-shaped structure with sepeated upper and lower parts.

5. Optional accessories of horizontal CNC lathe: milling function, boring function, spindle indexing Axis C, grinding function, coolant device, internal tool-presetting device, automatic measuring device for workpiece, closed steady rest, open steady rest, hydrostatic steady rest and chip conveyor, etc.

Technical parameters of the overall two guide rails of horizontal CNC lathe:

Specification/Model | Unit | 颁碍611245×尝/骋 | 颁碍61160×尝/骋 | 颁碍61200×尝/骋 |

Max. Swivel Diameter | mm | 1125 | 1600 | 2000 |

Max. Turning Diameter over the Carriage | mm | 900 | 1250 | 1600 |

Max. Length of Workpiece | mm | 2000 - 20000 | 2000 - 20000 | 2000 - 20000 |

Max. Weight of Workpiece Between Centers | t | 12/20/32 | 12/20/32 | 12/20/32 |

Faceplate Diameter | mm | 1125 | 1600 | 2000 |

Spindle Speed Range | r/min | 0.8-160 | 0.8-160 | 0.8-160 |

Max. Cutting Force of Carnage | kN | Tool Plate 40/Tool Slide 25 | ||

Feed Range of Carriage (Longitudinal) | mm/min | 1-1000 | 1-1000 | 1-1000 |

(Transversal) | mm/min | 1-1000 | 1-1000 | 1-1000 |

Rapid Travel of Carriage (Longitudinal) | mm/min | 4000/6000 | 4000/6000 | 4000/6000 |

Tailstock Sleeve Travel | mm | 200 | 200 | 300 |

Main Motor Power | kW | 顿颁:37/5575 | 顿颁:37/55/75 | 顿颁:37/55/75 |

Feed Mode of Z Axis | When the working length is less than 5000mm, it is driven by a precision ball screw; when the working length is greater than 5000mm, it can be rotated by a double gear-rack with anti-backlash. | |||

Echnical parameters of the separation bed of horizontal CNC lathe with four guide rails:

Specification/Model | Unit | CK61160xL/G | CK61200xL/G | CK61250xL/G | CK61315xL/G | CK61350xL/W | CK61400xL/W | CK61500xL/W | CK61630xL/W |

Max. Swivel Diameter of Workpiece over the Bed | mm | 1600 | 2000 | 2500 | 3150 | 3500 | 4000 | 5000 | 6300 |

Max. Turning Diameter over the Carnage | mm | 1250 | 1600 | 2000 | 2500 | 2800 | 3300 | 4000 | 5000 |

Max. Length of Workpiece Between Centers L | mm | 5000-20000 | 5000-20000 | 5000-20000 | 5000-20000 | 5000-20000 | 5000-20000 | 5000-20000 | 5000-20000 |

Max. Weight of Workpiece Between Centers | t | 32/40/50/63/80 | 63/80/100/125/160/200 | 80/100/120/160/200/250/300/350/450 | |||||

Faceplate Diameter | mm | 1250/1600 | 1600/2000 | 2000/2500 | 2000/2500/2800 | 2500/2800/3150 | 2500/2800/3150/3500 | 2500/2800/3150/3500 | 3150/3500/4000 |

Max. Torque of Faceplate | kN.m | 80 | 80/125 | 125/160 | 160 | 160 | 200 | 250 | 315 |

Spindle Speed Rang | r/min | 0.625-125/0.8-160 | 0.625-125/0.8-160 | 0.625-125/0.8-160 | 0.625-125/0.8-160 | 0.4-80/0.5-100/0.625-125 | 0.3-60/0.4-80/0.5-100 | 0.3-60/0.4-80/0.5-100 | 0.2-40/0.25-50/0.3-60 |

Max. Cutting Force of Carriage | kN | 80/100 | 80/100 | 125 | 160 | 180 | 200 | 250 | 250 |

Feed Range of Carriage (Longitudinal) | mm/min | 1-1000 | 1-1000 | 1-1000 | 1-1000 | 1-1000 | 1-1000 | 1-1000 | 1-1000 |

Feed Rang of Carriage (Transversal) | mm/min | 1-1000 | 1-1000 | 1-1000 | 1-1000 | 1-1000 | 1-1000 | 1-1000 | 1-1000 |

Rapid Travel of Carriage (Longitudinal) | mm/min | 4000/4500 | 4000/4500 | 4000/4500 | 4000/4500 | 4000/4500 | 4000/4500 | 4000/4500 | 4500 |

Rapid Travel of Carriage (Transversal) | mm/min | 4000/4500 | 4000/4500 | 4000/4500 | 4000/4500 | 4000/4500 | 4000/4500 | 4000/4500 | 4000/4500 |

Transversal Travel of Carriage | mm | 675 | 800 | 1000 | 1250 | 1400 | 1800 | 1800 | 2150 |

Tailstock Sleeve Travel | mm | 200 | 200 | 300 | 200 | 200 | 300 | 300 | 300 |

Main Motor Power | kW | 55/75/90/110/132/160 | 110/132/160 | 132/160/200/250 | |||||

Industry-customized solutions of horizontal CNC lathe:

Facing the diverse processing needs of the European and American markets, we provide customers with in-depth customized solutions for horizontal CNC lathe. We have customized and developed a horizontal CNC lathe for the processing of ultra-large wind power spindles for a well-known energy equipment company in the United States. In view of the ultra-long, overweight and high-precision processing characteristics of the wind power spindle, we broke through the design limitations of the traditional horizontal CNC lathe and re-optimized the structure of the horizontal CNC lathe. The overall casting bed is thickened and widened to enhance the rigidity of the horizontal CNC lathe, and the horizontal CNC lathe is equipped with a high-precision dual-axis linkage tailstock, so that the horizontal CNC lathe can be used for up to 12 years. During the processing of the workpiece of meters, the cylindrical degree error is controlled within ±0.01mm. At the same time, combined with the special surface treatment process requirements of customers for horizontal CNC lathe, the grinding accessories and cooling system of exclusive horizontal CNC lathe are customized to fully meet the strict standards of horizontal CNC lathe in the wind power industry.

Participate in the co-creation of new products of horizontal CNC lathe:

If you have unique insights or new feature ideas for horizontal CNC lathe, please leave a message to tell us. Your creativity may become the core highlight of our next generation of horizontal CNC lathe new products! Participating in the co-creation of new products of horizontal CNC lathe will not only allow horizontal turning lathe to meet your needs, but also have the opportunity to enjoy the priority experience of horizontal turning lathe or the exclusive discounts of horizontal turning lathe and other benefits.

Linkage machining capabilities of heavy duty horizontal lathe:

Our heavy duty horizontal lathe is equipped with an advanced multi-axis linkage control system and has the composite processing ability of multi-axis linkage. This means that the workpiece only needs to be clamped once, and heavy duty horizontal lathe can complete multiple complex processes. Heavy duty horizontal lathe, an efficient and high-precision composite processing model, can perfectly match the strict processing needs of complex and heavy parts in European and American aerospace, energy equipment manufacturing and other fields. Heavy duty horizontal lathe can help enterprises reduce equipment investment and process turnover time, and heavy duty horizontal lathe can also improve the overall production efficiency of enterprises.

Intelligent automated processing of heavy duty horizontal lathe:

Heavy duty horizontal lathe is equipped with an intelligent automated machining ecosystem, which has great advantages in the automatic tool change process. Heavy duty horizontal lathe's automatic tool change system adopts high-speed servo drive technology, short tool change time, and high tool magazine capacity. Heavy duty horizontal lathe can meet the tool needs of various complex machining tasks. At the same time, the system of heavy duty horizontal lathe has intelligent tool management functions. Heavy duty horizontal lathe can also monitor the wear of the tool in real time. When the tool life of heavy duty horizontal lathe is close to the limit, heavy duty horizontal lathe will automatically trigger the tool change command and adjust the processing parameters to avoid waste due to heavy duty horizontal lathe tool problems.

Advantages of horizontal turning lathe:

1. Horizontal turning lathe greatly improves production efficiency:

CNC system of horizontal turning lathe can effectively shorten the preparation time before production and effectively improve the cutting time ratio. The CNC system of horizontal turning lathe will calculate the best cutting parameters and cutting plan to improve production efficiency.

2. The processing quality of the horizontal turning lathe is higher:

Horizontal turning lathe is very stable for the machining accuracy of the workpiece, because the automatic setting of the CNC program of horizontal turning lathe is not subject to manual intervention, and the software correction achieved by the machining accuracy has reached higher precision.

3. Horizontal turning lathe is can realize multiple uses in one machine:

Horizontal turning lathe perfectly realizes one machine with multiple functions. For example, the machining center of horizontal turning lathe can automatically control the tool change through the CNC system, and complete the processing of all processing parts after one clamping, which effectively saves economic expenses, plant area and maintenance of multiple lathes.

4. Horizontal turning lathe is highly adaptable and flexible:

As long as the horizontal turning lathe program is set and changed, the machining of new types of workpieces can be realized, which cannot be realized by ordinary machine tools, and the machining of complex surfaces of new workpieces can be flexibly realized without waiting too long for innovation.